Authors: Andrej Kregar, Andrej Šenk, Neja Kaligaro

Project year: 2016

Link: Linolit

The company Polirtlak d.o.o. is specialized in the manufacture of concrete floor grinding machines. To achieve the differentiation of products on the market, they approached us with the desire to redesign their line of polishing and grinding machines Linolit. We were faced with the challenge of creating a unified line of three different grinding machines with differences in size and structure while still keeping them in the lower price range.

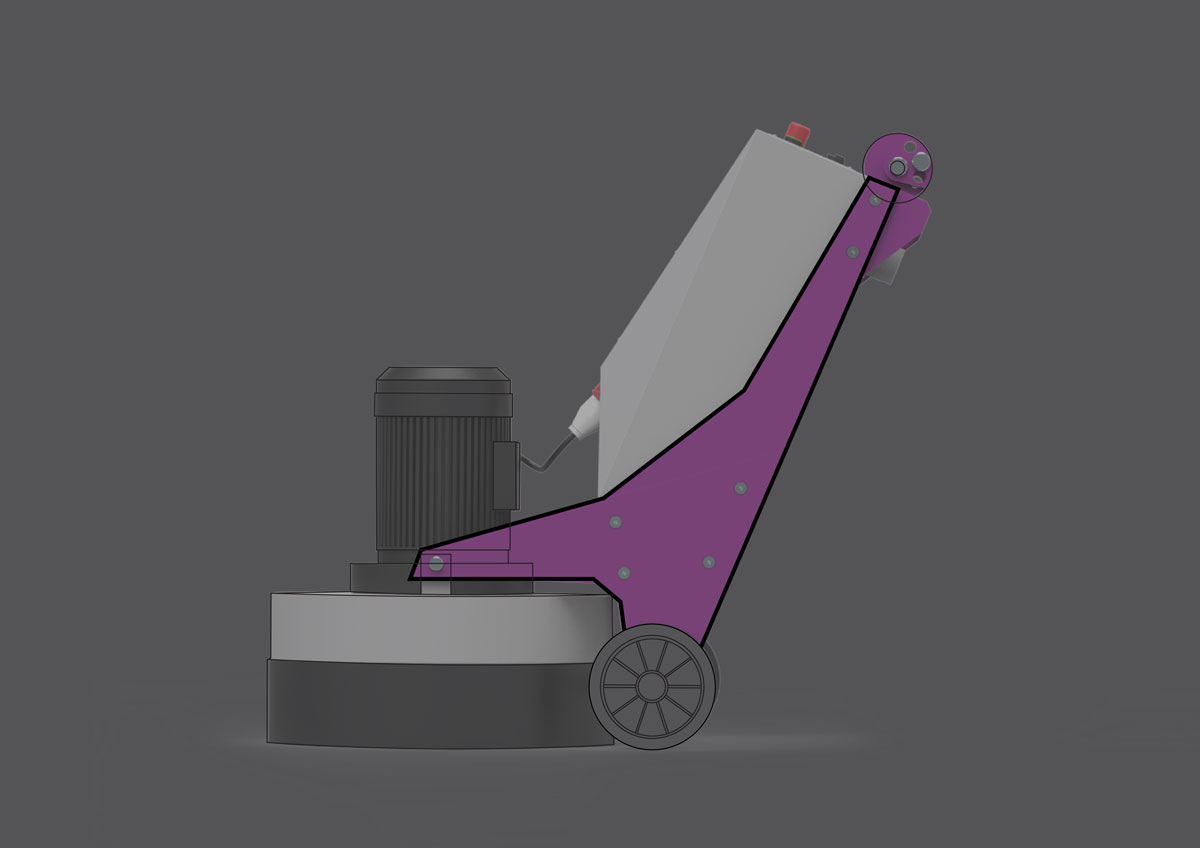

We began the design process with a detailed analysis of the machines (their constituent elements, function, user interaction) and extensive market research. The conclusion was that apart from the unique purple color, Linolit didn’t differ substantially from the other manufacturers.

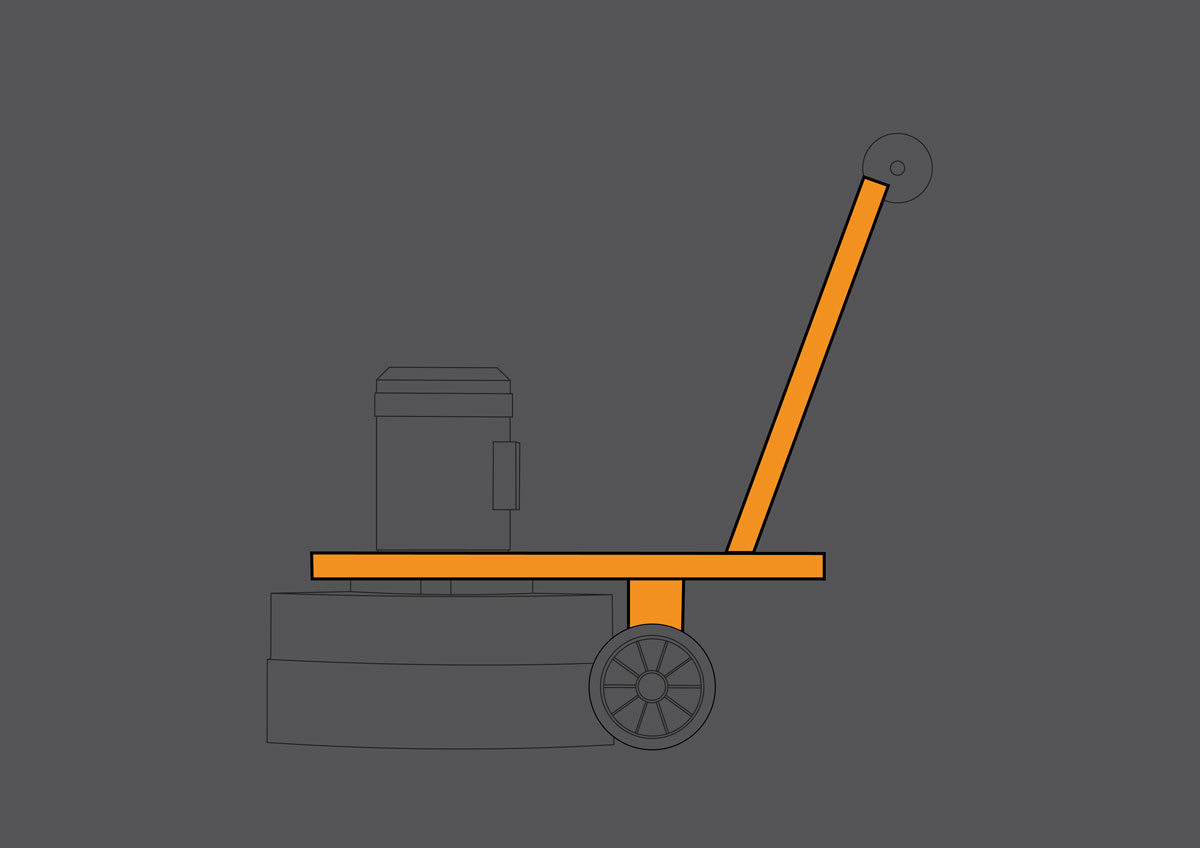

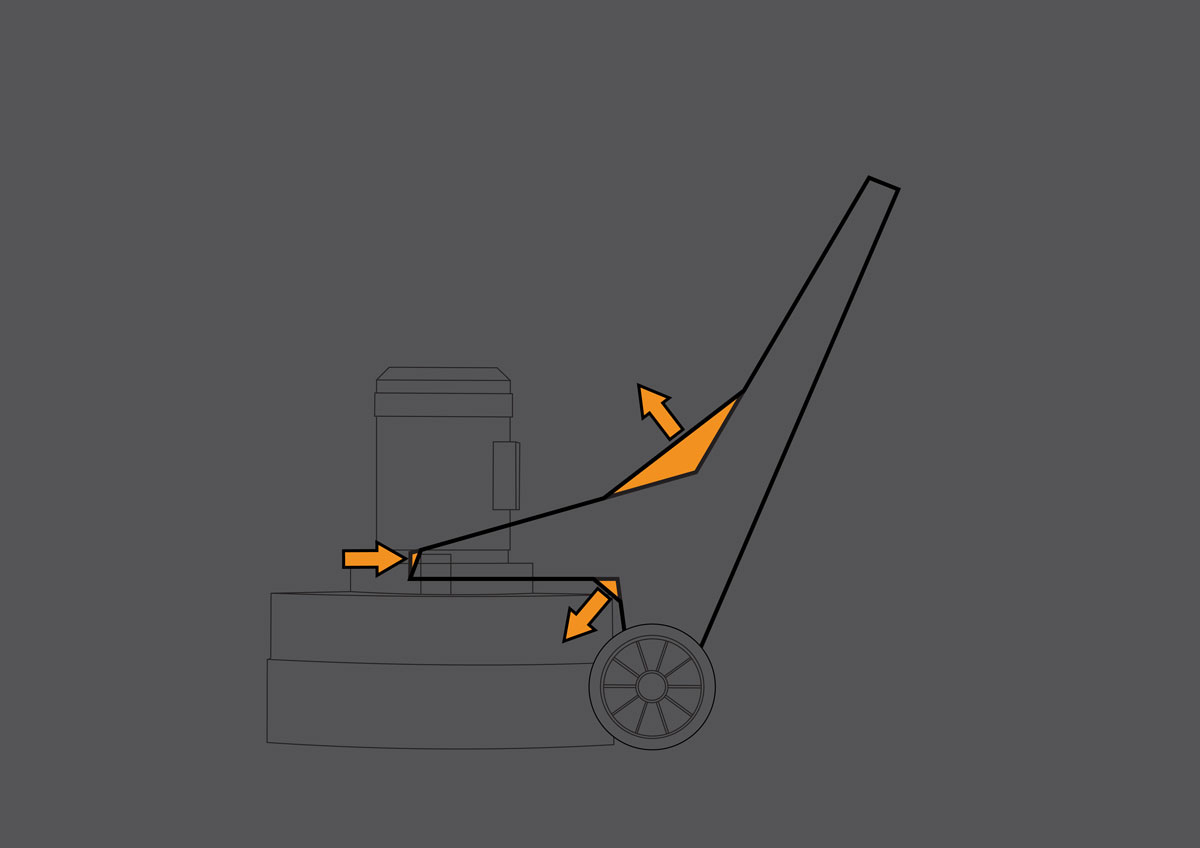

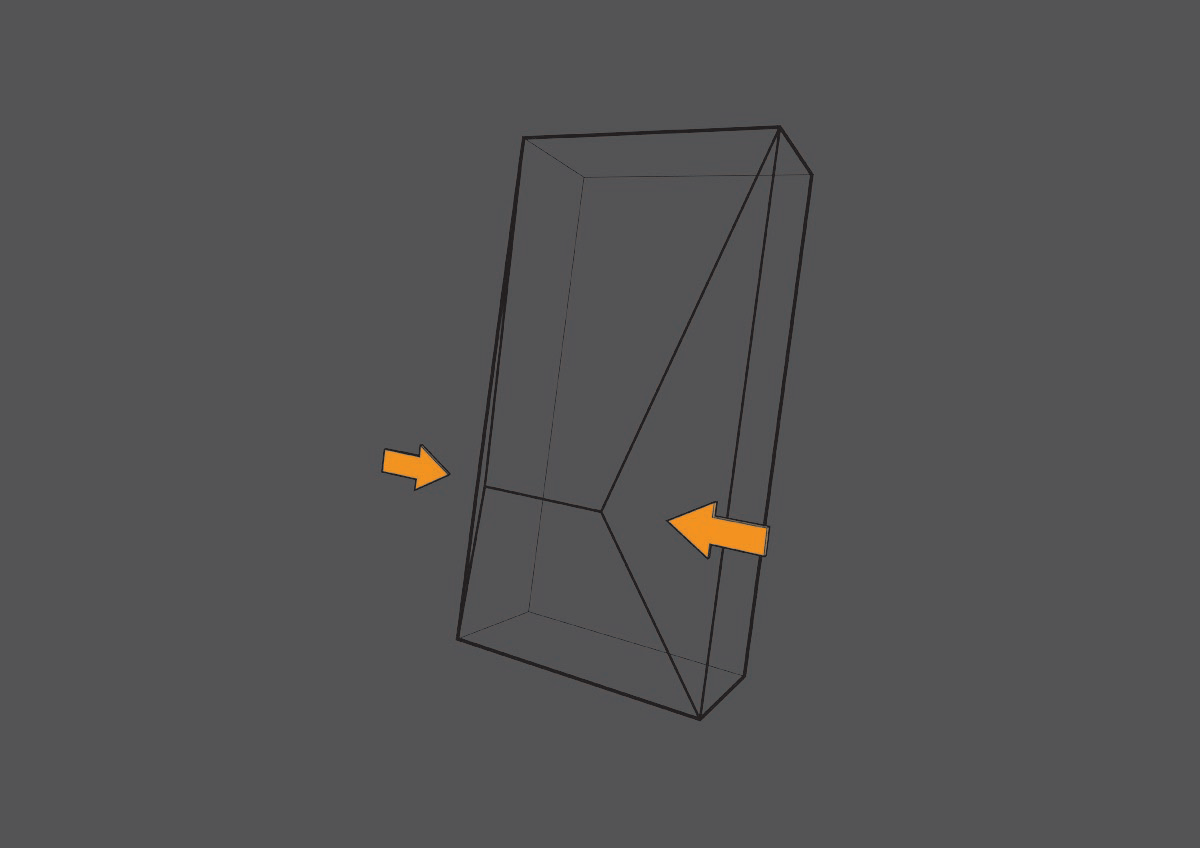

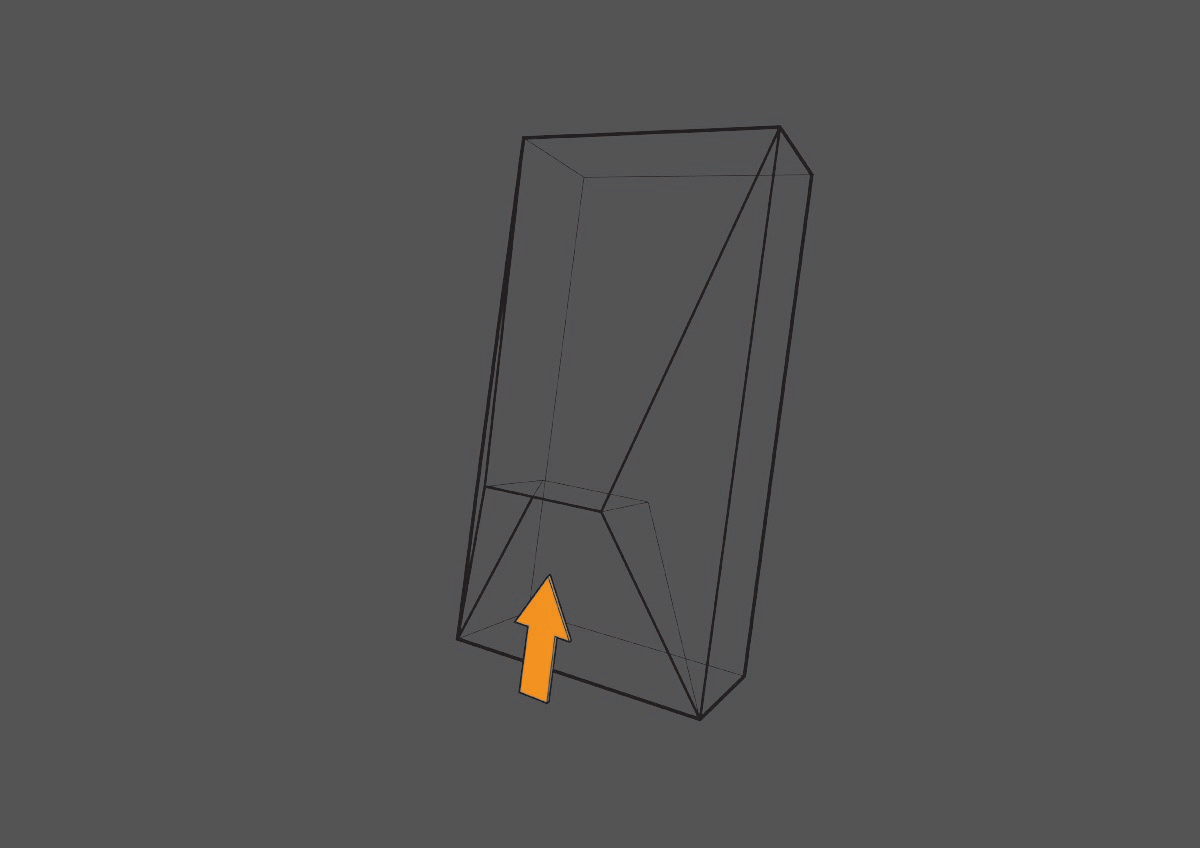

When designing these machines, the primary focus was on two main elements – the construction and the metal box.

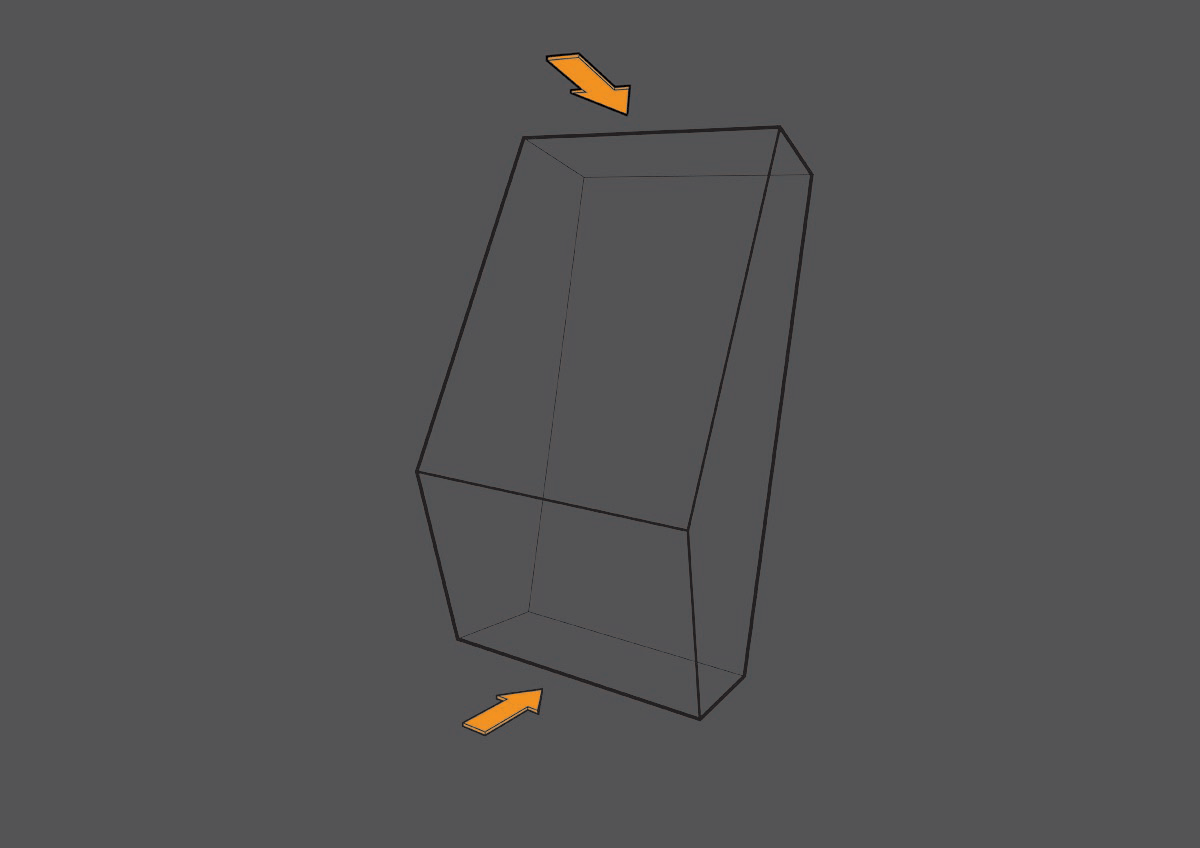

Our geometry studies are based on our initial sketches, and the introduction of these elements gets incorporated into polishing machines. The existing technology of producing the basic structure from steel profiles did not allow many design changes, so we changed the manufacturing process. By introducing the laser cutting of sheet metals, we managed to give the main structure any desired shape.This change simplified and accelerated the production and reduced the amount of manual work needed, thus the deviation and errors in the manufacturing process.

The housing is the most visible element of the machine, and by changing it, we wanted to give it a robust, professional appearance and highlight the engineering and manufacturing quality. We used straight, sharp lines of the basic structure on the metal casing and the same design language on all three machines to unify them despite minor differences.

Our work resulted in a new generation of grinding and polishing Linolit machines, characterized by a thought-through geometry and unified design language.